Custom Specialty Electric Motors

Louis Allis has been serving industries with custom electric motors for over 100 years. We specialize in manufacturing custom three phase industrial electric motors for some of the most demanding applications worldwide. For over a century the industries of the world have turned to Louis Allis to manufacture electric motors for their most specialized applications. Louis Allis is certified for MIL-STD-2037 Navy Sealed System Windings meaning our marine and naval vessel motors and services meet and exceed the standards required by the US Navy.

Whether your need is AC Induction Motors, AC Wound Rotor Motors, AC Synchronous Motors, or DC Motors, there’s a reason why Louis Allis has always been the “First and Last Name in Electric Motors."

Motor types and applications include but aren't limited to:

- Ball Mill Motors

- Bow Thruster Motors

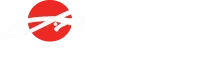

- Conveyor Motors

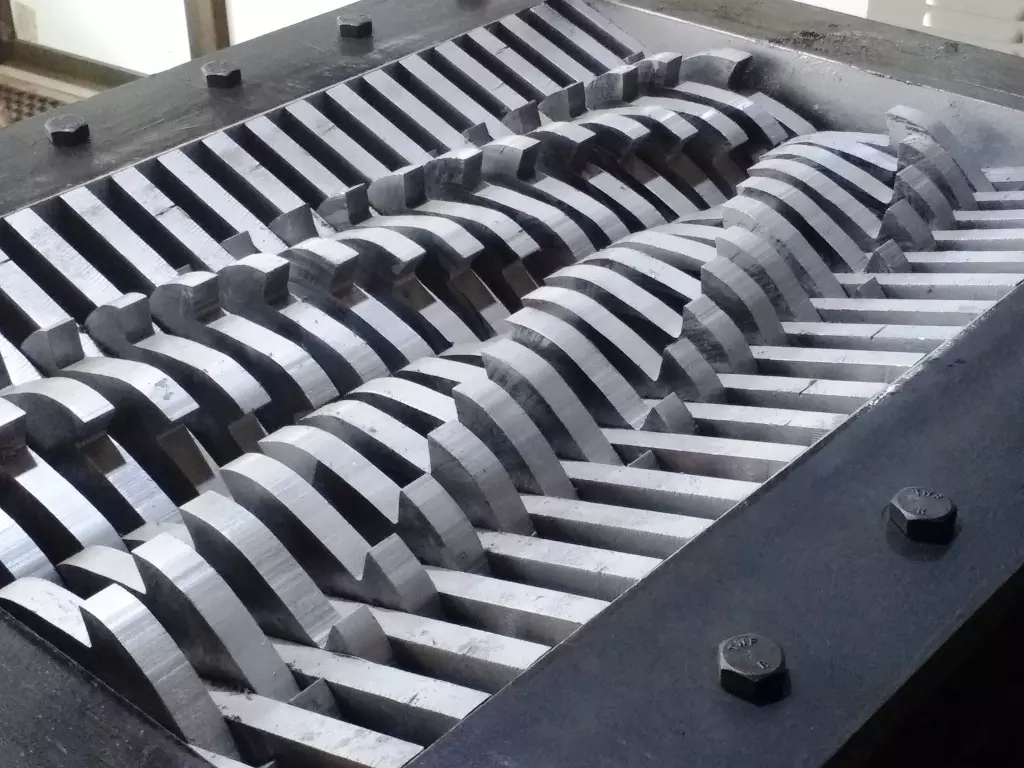

- Crusher Motors

- Dredge Motors

- ID Fan Motors

- Kiln Drive Motors

- Large DC Motors

- Pulverizer Motors

- Shredder Motors

- Vertical and Horizontal Pump Motors

- Winch and Hoist Motors

- High Torque Motors

- Compressor Motors

- Ventilation Motors

- Mixer Motors

- Press Motors

- High Speed Motors (>3600 RPM)

Louis Allis has a wide range of manufacturing and design capabilities for any specialty electric motor. We are also able to modify stock electric motors for your specific use case.

- AC induction (Squirrel cage)

- Wound rotor

- Synchronous

- DC

- Vertical

- Design D (High slip)

- Multi-speed

- Shaker/vibratory duty

- Pancake style

- Crusher/pulverizer duty

- Drill rig motors

- Compressor duty

- Fan duty (High inertia)

- Centrifuge/extractor duty

- Mixer duty

- Nuclear applications

- Military motors (MIL-SPEC)

- Specialty three phase electric motors specifically designed to meet the needs of your application

- Low, medium, and high voltage specialty three phase motors up to 20,000 HP available

- Manufactured at Louis Allis’ ISO 9001:2015 certified facility in Warrior, Alabama

With more than 100 years of experience, Louis Allis has a valuable portfolio of legacy designs and projects at its disposal. Louis Allis utilizes these legacy designs to provide the following:

- Duplication of legacy Louis Allis motors and generators

- Modification of legacy machines

- Provision of data including performance information for legacy products

- Provision of spare parts information

Louis Allis can design and build a "Fit and Function" replacement for any large or specialty electric motor regardless of the original motor OEM.

- Reverse engineering services

- Providing on-site engineering to collect critical information required for building a "fit and function" replacement

- Opportunity to incorporate any design improvements or modifications when building replacement motors

A customer needed more horsepower in the same frame size as their original motor. They also needed a spare motor to match. Originally their motor was 450 HP, they needed to increase it to 600 HP.

A customer needed more horsepower in the same frame size as their original motor. They also needed a spare motor to match. Originally their motor was 450 HP, they needed to increase it to 600 HP.

Louis Allis was able to design a new motor with the horsepower they needed and the same size frame as the original motor. Louis Allis was also able to salvage their old motor as a spare. We were able to bump up the horsepower, save them downtime, and save them from having to purchase a second new motor.

Quality Craftsmanship

Quality is our top priority for new electric motor manufacturing and electric motor repair at our ISO 9001:2015 certified facility. We live by the motto "Quality applied with Louis Allis pride".

Recertified Motors

Our Factory Recertification Program exists to help customers who need a quick solution to a problem that can’t wait for a custom build.

Full Service Shop

At Louis Allis we have the capability of repairing a variety of electric motors, regardless of manufacturer or severity of repair needed.